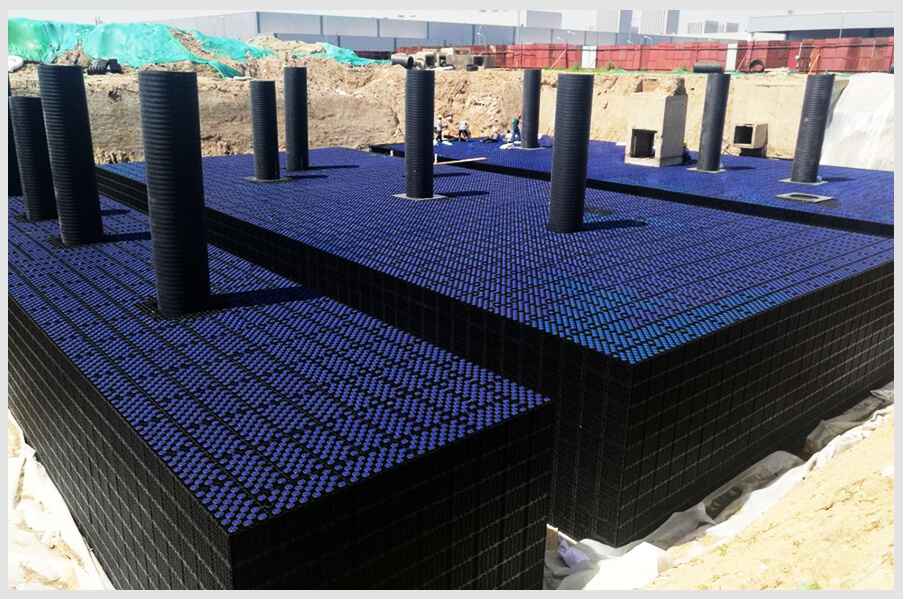

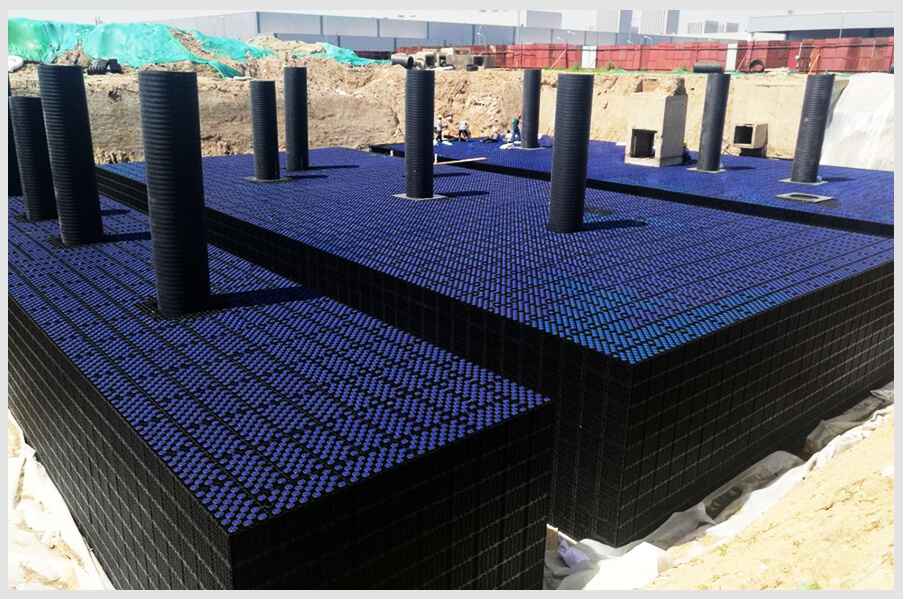

Underground water storage module

The storage box is made up of polypropylene plastic module cells, forming an underground storage pond, according to the requirements of the project, wrap anti-infiltration earthen cloth or one-way infiltration

earthen cloth around the pond, forming the two different types of water storage pond and infiltration water regulation pond. The installation of water storage box is convenient, with large bearing capacity. Do not breed mosquitoes and flies and algae to ensure water quality, and after the provisional construction area is put into use, it can be disassembled and removed to other regions for continual use. The equipment applies to the rainwater collection and utilization in large buildings, residential blocks, industrial parks, squares and workshops.

SLMK-IV Storage box

| Name |

Assembly monomer size |

Assembly monomer size |

| Size |

L×W×H=1000×500×400mm |

L×W×H=1000×500×200mm |

| |

A |

B |

| Single group vertical compressive strength |

Breaking |

>450kN/m2 |

>300kN/m2 |

| Lateral bearing capacity |

Strength |

>190kN/m2 |

>100kN/m2 |

| Multi-group assembly vertical

bearing strength |

>350kN/m2 |

>250kN/m2 |

| Multi-group assembly lateral bearing strength |

>150kN/m2 |

>90kN/m2 |

| Oxidation induction time |

(200℃,≥20min) |

| Chemical resistance |

Quality change rate |

≤0.5% |

| Chemical resistance |

Size change rate |

≤0.5% |

| Impact test |

(4.0kg heavy hammer, 2.0m height drop) No cracking, no damage, no deformation. |

| Oven test |

(150℃ , 30min) No cracking, delamination and bubbles |

| 50-year long-term creep performance |

Deformation rate after 50 years minus 10h is ≤1%. |

| Material |

Polypropylene, recycled polypropylene |

| Water storage rate |

>95% |

| Manufacturing method |

Precision injection |

- Foundation pit excavation and foundation treatment

- Rebar lashing

- Installation of seepage pipe

- Concrete foundation pouring

- Module stacking

- The main body of the module is installed